Digital printing

Marketing Essentials

ONLINE DIGITAL PRINTING SERVICES IN DELHI-NCR- GURGAON, DELHI, NOIDA

We at InkPrint provide excellent personalized online printing services. We have been successfully catering to our clients with impressive digital printing services. Through us, get your interactive business projects adorned with a myriad of colors and stunning designs to create a lasting impression. Simply, visit our online platform, customize your preferences, and place your order from the comfort of your office or home.

Our commitment to delivering exceptional quality and superlative customer experience makes us one of the best printing services provider in Delhi. Do you have a creative business idea for your upcoming marketing event? Let our team of experienced professionals help you transform your marketing idea into memorable digital-printed marketing products. We help you in easing out the process of printing through the convenience of online ordering, secure and safe payment options, free delivery to your doorstep, and 24×7 customer care services. That is surely the best way to improve your brand image with premium Online Printing Services India from InkPrint!

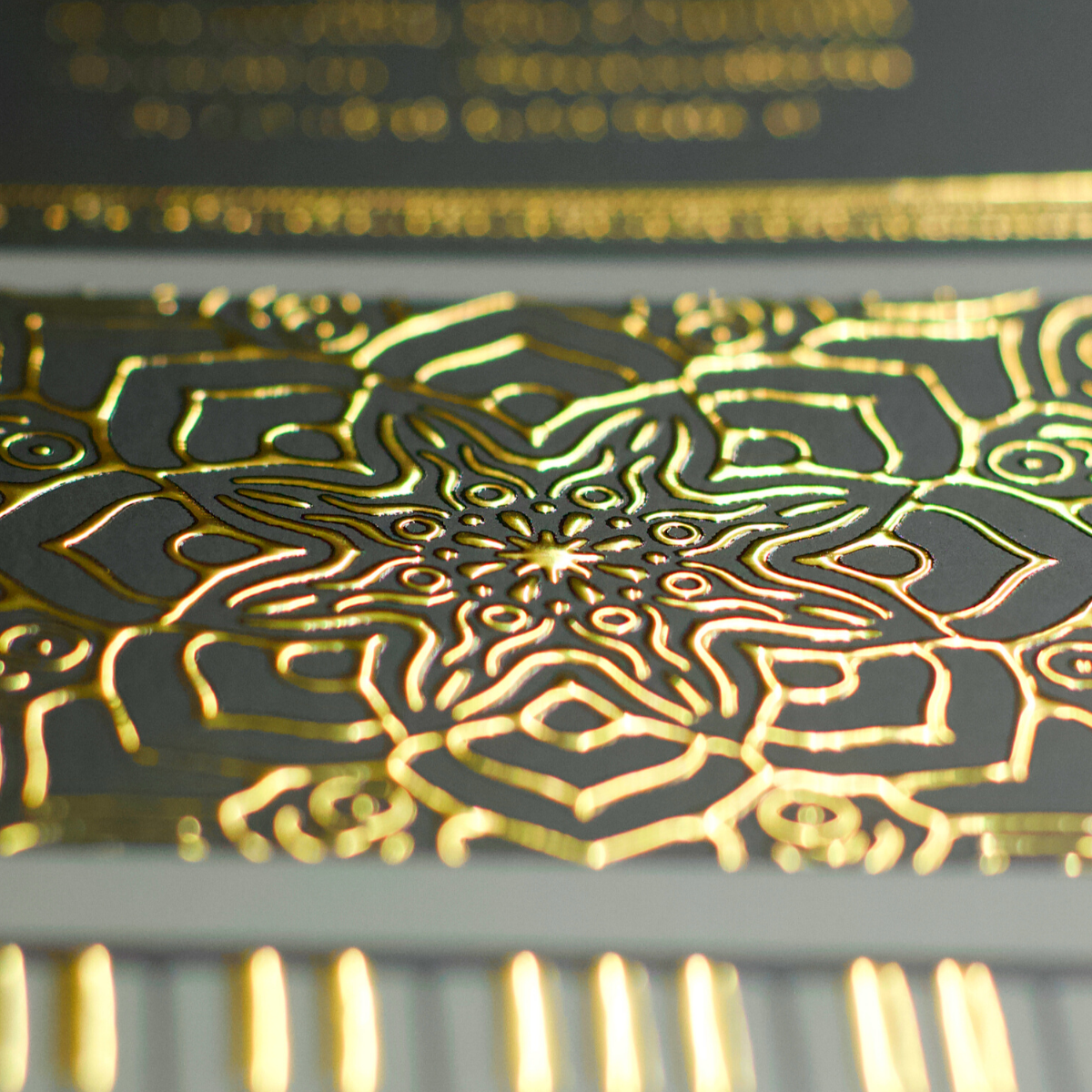

TRUST ONLY THE BEST OFFSET PRINTING PRESS IN DELHI

Our years-long industry experience in offset printing helps us to deliver supreme print quality in every printing job. We have been constantly upgrading our printing technology to keep pace with the evolving technological trends. Our high quality, latest machines fabricate quality throughout the printing process. To complement, our design principles based on traditional quality offset printing ensure production of immaculate business marketing solutions. In addition, we follow a transparent procedure from conceptualization to customization and delivery that meets your satisfaction. Therefore, confidently promote your brand through our affordable, turnkey marketing collaterals.

WHY CHOOSE INKPRINT FOR YOUR DIGITAL PRINTING AND OFFSET PRINTING SOLUTIONS?

Our extensive experience in the field of digital printing and offset printing help us deliver superlative custom printing services in faster turnaround time. Here are vital features that make us the best digital and offset printing solution providers in Delhi:

- Multiple printing options – We cater to diversified printing options like short runs, variable data printing, print on demand as well as personalized printing solutions in swift turnaround time.

- Versatile business marketing solutions – We offer a huge collection of marketing products to help you boost your business. Select from our online collection of printed business marketing solutions to create brochures, newsletters, posters, flyers, business stationery, catalogs, magazines and more. Our versatile printing methods and advanced printing quality help us deliver nothing less than the best for our clientele.

- Reliable printing services – We at InkPrint believe in delivering reliable as well as high-quality digital printing services in India. Our online print shop makes possible to serve our customers until their utmost satisfaction. Whether you need impressive business cards and letterheads or flyers and banners for your upcoming marketing event, you will get everything personalized to your specific business requirements. We convert your ideas to print until you are satisfied with the results.

- Exceptionally good customer service – We ensure an excellent customer experience right from the order placement to delivery. Our cordial experts are available to take customer queries. Besides, our immaculate after-sale services ensure utmost customer satisfaction.

- Cost-effective printing services – Our exceptional value-for-money deals get you the best services at most affordable prices.

- Flexible payment options – You can visit our online printing store and place your orders. You are free to pay online or select from alternative payment options like cheque or NEFT.

REACH OUR TEAM TO CUSTOMIZE YOUR PREFERENCES

Our team will help you decide what packages will suit your business preferences. Get100, or 200, or 500 or more visiting cards, letterheads, stationery envelopes, brochures, etc.to complement your business activities from our offset Digital Printing. Marketing the product becomes easy when you have the right material to give away. If you like publicity through the flyers, then that is the way to start.

It is an investment that helps a business to grow in the right direction. Get the words composed and pass it on to us. As the best online printing services in Gurgaon, we will deliver the items you need in double-quick time. Office brochures are the best if you have plenty of visitors who are potential customers. Handing out brochures through the marketing department will take care of expanding your customer base. Let us make your day brighter with the attractive company brochures that highlight your business goals and ambitions in the best possible manner.

OUTDOOR PRINTING SERVICES

Or, perhaps your business needs Banners and Standees. This makes passers-by to take note of your shop and perhaps drop in with their own requests. If your business is a crowd-popular one, then this is the best alternative. You don’t have to invest much, and you get all the attention you need. Choose the colors your business needs and you have the banner you want. We make your dreams a reality through our innovative printing solutions.

You can even have calendars and diaries printed as memorabilia for the staff and your regular customers. There is no better way to thank them for their participation in your success. Be there with them when they need you; give them the tokens of appreciation, and you are sure to make your business grow.

So, what are you waiting for? Join hands with the best printing press in Delhi, for all your print-related solutions!